This is no time to be delicate; the main risk comes from the spit that everyone has in their breath to some extent. Droplets of spit can be so small as to be nearly invisible, but they carry viruses among other things. Thus the immediate goal for health purposes is to prevent those droplets from landing on the surface of a microphone, where they could be passed along to the next user of that microphone, or to the engineer who handles it. A thin plastic bag pulled over the microphone, neither too tightly nor too loosely, will effectively protect the microphone.

See www.bonedo.de/artikel/einzelansicht/lassen-sich-mikros-mit-plastiktueten-vor-viren-schuetzen.html for the photos, even if you don’t understand the German text.

(The article is mainly concerned with reporters’ use of hand-held microphones for interviews, but the same principles apply elsewhere as well. The bag should be as thin as possible for minimum effect on sound quality, but it must be free of holes. And while the article doesn’t mention this, the bag must obviously be changed after each person uses the microphone, or else it itself will become a vehicle for contagion.)

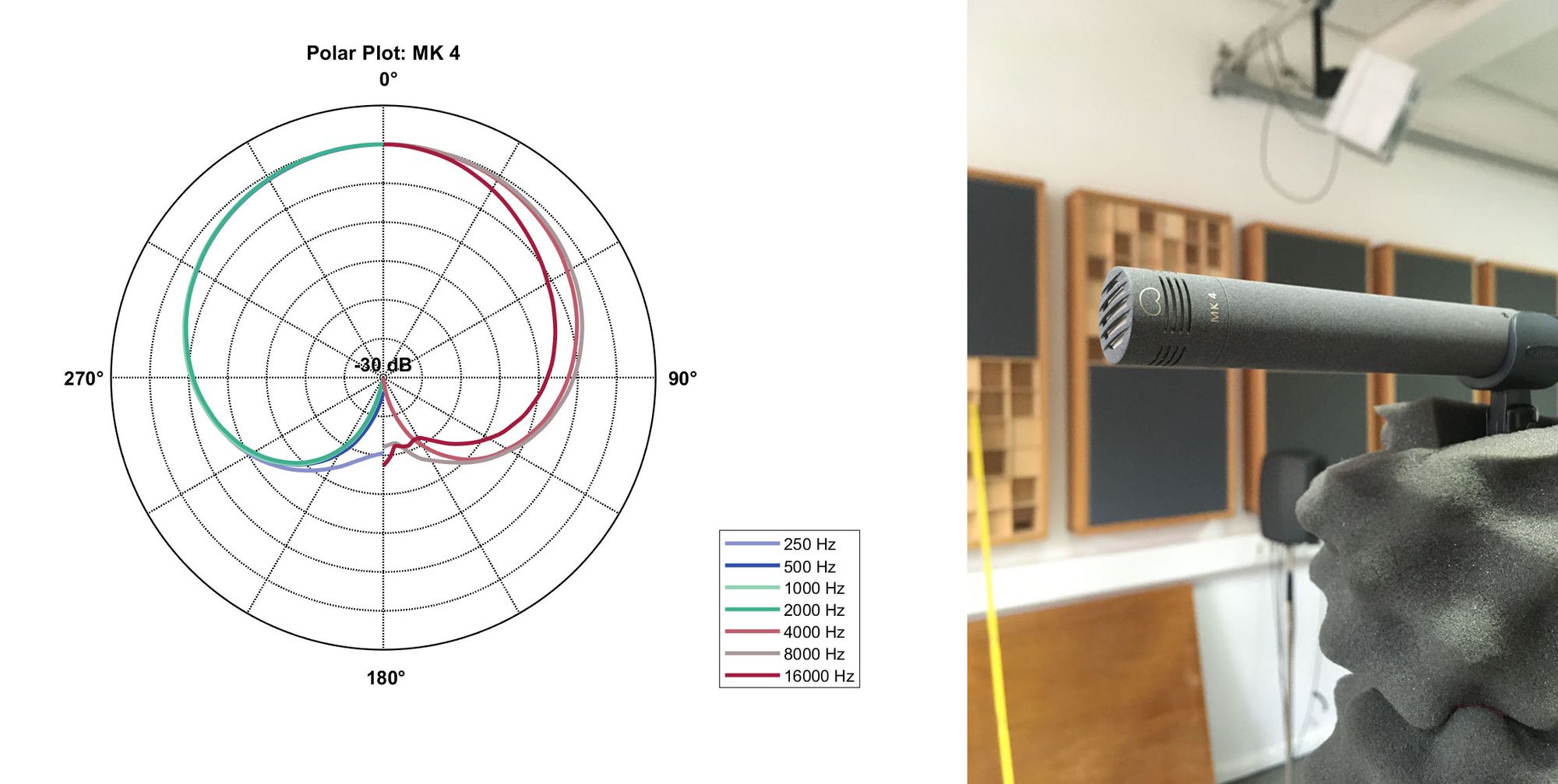

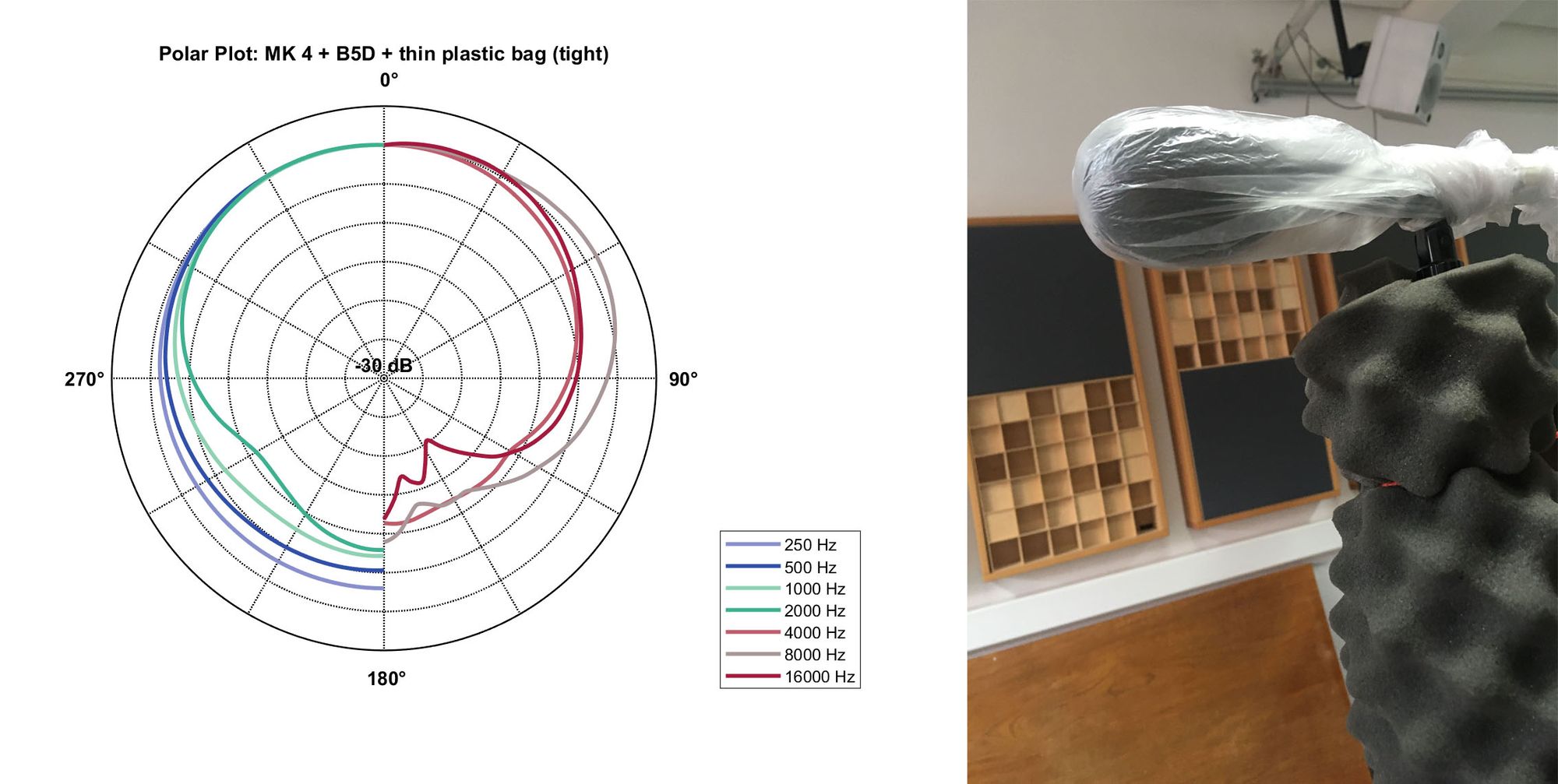

The plastic bag changes the transfer function of the microphone, so this method should only be used if absolutely necessary. The thicker the plastic bag, the greater the risk of disturbing resonances and a loss of higher frequencies. When using a plastic bag, the directivity at lower frequencies decreases significantly, especially if it is very tightly stretched. This is illustrated by the following measurement: