Air always contains some amount of water vapor, and can absorb more of it at high temperatures than at low ones. The amount of water vapor in air, expressed as a percentage of the maximum amount that could be held by air of that temperature, is the relative humidity. If the temperature changes, the relative humidity will change as well. At or above 100% relative humidity, water droplets can form (condensation).

Our microphones function very well at almost any steady level of humidity. SCHOEPS microphones are specified to work correctly up to a relative humidity of 90% as measured at 25° C (77° F). All our microphones are required to pass testing under these conditions.

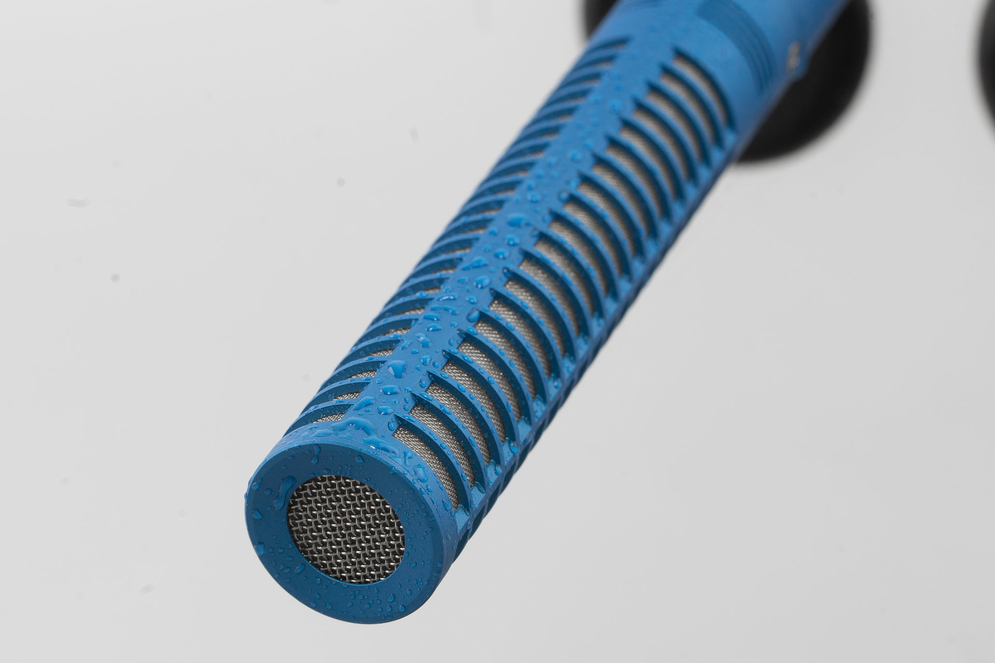

But condensation within a capsule—whether it is DC-polarized like ours or RF-based—can disrupt the capsule’s functioning, since it can bridge parts which must be isolated electrically from one another. Condensation is the change of the state of water from the gas phase into the liquid phase; see Wikipedia.org/Condensation. Condensation mainly results from changes in temperature and humidity–especially if they are abrupt–rather than from any “steady-state” conditions. Condensation creates water droplets. These water droplets will attach to material which is colder than the air. Glasses wearers know what is meant here: In winter, glasses that are still cold will fog up immediately when entering a warm room. Bringing a microphone from indoors to outdoors or vice versa, can cause an abrupt change in temperature (and thus humidity) both for that microphone and the air around it. The water droplets will attach to the cold metal parts in the microphone and will make it fail.

A further consideration: Microphones used in dusty environments, and/or that are used to pick up speaking or singing voices at close range, can accumulate deposits inside them. This contamination, combined with water droplets (e.g. created by condensation of moisture), can create a leakage path for the charge placed on the diaphragm. The result can be noise--rumbling, crackling or whistling sounds, which can be quite severe—or even some temporary loss of signal. There is a mutual cause-and-effect relationship here, since high humidity both promotes such deposits and causes deterioration of performance when they are present.